Making microalgae big: Scaling up production is key to food security success

"We may have stumbled onto the next green revolution,” says lead author of the paper and professor of earth and atmospheric sciences at Cornell University, Charles H. Greene.

"I think of algae as providing food security for the world," he says. "It will also provide our liquid fuels needs, not to mention its benefits in terms of land use. We can grow algae for food and fuels in only one-tenth to one one-hundredth the amount of land we currently use to grow food and energy crops.”

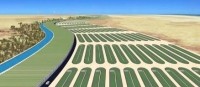

But, according to the researchers at Cornell University, it is large-scale industrial cultivation of marine microalgae (ICMM) that offers the most potential for food security, although this is not immediately in sight.

“Ramping up this production to a globally relevant scale will take additional decades to accomplish," reads the commentary.

"By the second half of the century, large-scale ICMM can help society achieve net-negative fossil carbon emissions; produce the liquid, energy-dense hydrocarbon fuels needed to power the heavy-vehicle, shipping, and aviation components of the transportation sector; and supply the necessary protein to feed an increasingly crowded world.”

Algae players

The algae sector is growing fast and big players like DSM and Roquette are invested. Smaller firms like Israel-based Hinoman cultivates microalgae on a commercial scale while Green Onyx, also from Israel, allows consumers to grow khai nam duckweed in the comfort of their own homes thanks to home devices.

The authors point out that scaling up microalgae production on land may be more effective than the sea, and the fact that freshwater is not required means cultivation would not compete with other agricultural crops for water - an increasingly scarce resource in arid, sub-tropical regions that are best suited to microalgae cultivation.

The costs of inaction

However the costs of setting up a commercial plant are currently prescriptive - at least in monetary terms.

The researchers estimate that a 2,500 acre commercial microalgae facility would cost between $400 million (€376m) to $500m (€470m) to build.

"That may seem like a lot of money, but integrated solutions to the world's greatest challenges will pay for themselves many times over during the remainder of this century,” says Greene. The costs of inaction are too steep to even contemplate.”

"We can relieve the pressure to convert rainforests to palm plantations in Indonesia and soy plantations in Brazil. We got into this looking to produce fuels, and in the process, we found an integrated solution to so many of society's greatest challenges."

Source: Oceanography

"Marine Microalgae: Climate, Energy and Food Security From the Sea."

Available onlineahead of print, https://doi.org/10.5670/oceanog.2016.91

Authors:Greene, C.H., M.E. Huntley, I. Archibald, L.N. Gerber.