Interpack 2017

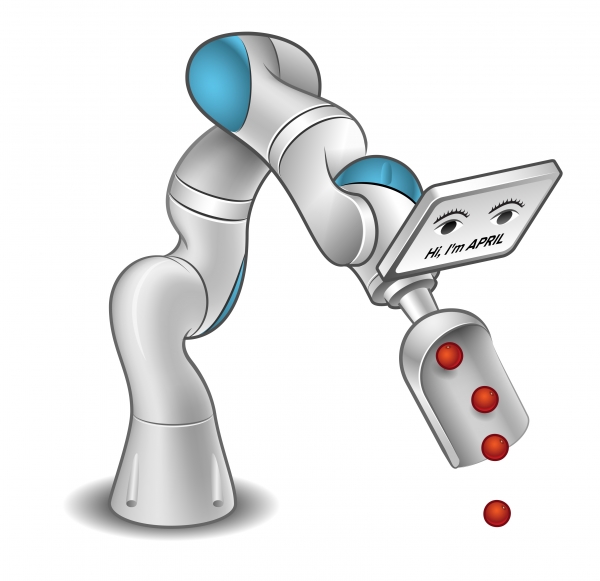

APRIL Robot Chef signs autographs at Interpack

The automated dry weighing system is the latest in OAL’s range of machinery following a joint project with the University of Lincoln on its APRIL robotic chef development and two other Innovate UK projects focused on steam infusion high speed cooking and cryogenic cooling of food products.

National Centre for Food Manufacturing

“The time is right for robotics. There have been a couple of false dawns but the industry needs a productivity boost and the technology is now available at the right price,” said Stephen White, lead automation engineer, OAL.

“APRIL is a great example of this in the way she uses robotics to simplify how we cook food. We’re able to emulate how you would cook at home with small batches with up to half the amount of capital of equipment required in a traditional system.

“The University of Lincoln is a fantastic industrial partner and we’ve accelerated the progress of the project by working at the National Centre for Food Manufacturing.

“Working in an SME we’re very quick to jump on new ideas that can span many engineering disciplines. It’s vital to be able to access the advanced knowledge across the University of Lincoln from robotics to advanced modelling.”

The one-year project supported by a £448,850 grant from the UK Government via Innovate UK and the EPSRC's Robotics and Autonomous Systems (RAS) research fund, will focus on automating the processes of handling, weighing and transporting raw ingredients in the food and beverage industry.

Processing technologies

It will also develop hygiene and food safety features which will be crucial when using robotic production systems within the food manufacturing sector.

By automating the handling and movements of raw ingredients, the researchers expect to make major advances in efficiency, quality and quantity in the production of food products such as sauces and soups when compared with traditional processing technologies.

The research will take place in the Robotics & Automation Zone of the National Centre for Food Manufacturing at the University of Lincoln's Holbeach Campus in South Lincolnshire, in the UK.

"This project tackles directly many of the technical and scientific challenges in material handling for robotic automation of food manufacturing processes. In doing so, it will greatly enhance the potential for companies of all sizes to embrace the improvements in productivity, sustainability and quality which these technologies make possible,” added Mark Swainson, deputy head and lead for Research and Higher Education, the National Centre for Food Manufacturing.

According to Jake Norman, sales and marketing manager, OAL, the industry will see a dramatic rise in the number of robots and by launching the APRIL Robotics Weighing Station it is connecting with food manufacturers that are looking to automate their ingredient preparation.

Interpack tradeshow is held in Dusseldorf, Germany.